The Oak Ridge National Laboratory, also known as ORNL, is consistently on the cutting edge of additive manufacturing innovation. In a recent initiative, ORNL researchers have developed plant-based 3D printing materials which not only make use of biofuel byproducts but also demonstrate improved inter-layer adhesion for printed parts.

The material in question is made from a combination of rubber, carbon fiber, acrylonitrile butadiene styrene (ABS) and lignin, which is the key ingredient. Lignin, a key structural material in plant tissues, is also a byproduct of biofuel production processes. In other words, finding a use for the organic polymer could be beneficial to all involved as it would cut back on biofuel byproduct waste, could offer biorefineries an addition form of income and be used to produce better 3D printing plastics.

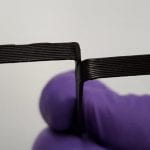

In terms of printability, the ORNL team says its plant-based material has excellent properties and performance: as lignin naturally adds sturdiness to plant cell walls, the material offers a similar function in the 3D printing material. In fact, when printed, the material has demonstrated 100% improved weld strength between the layers of ABS.

“To achieve this, we are building on our experience with lignin during the last five years,” commented ORNL’s Amit Naskar. “We will continue fine tuning the material’s composition to make it even stronger.”

A study recently published in the journal Applied Materials Today delves into the material’s development further and explains how using melt-stable lignin (sourced from biorefineries) in combination with ABS, acrylonitrile-butadiene rubber and carbon fibers resulted in a highly printable material with “100% improved inter-layer adhesion strength.”

For example, adding 10 wt.% nitrile rubber helped to toughen the ABS and lignin blend significantly, while adding 10 wt.% of carbon fibers helped to enhance the materials performance and decreased the degree of chemical crosslinking. In terms of lignin content, the researchers say they successfully 3D printed plastic composites with 40 wt.% of lignin.

Down the line, ORNL’s innovative lignin-based 3D printing material could provide a model for producing more plant-based thermoplastics for additive manufacturing and reduce the need for unsustainable petroleum-based thermoplastics.