Markets for Additive Manufacturing Using Refractory Metals: 2018-2027

$2,497.50 – $3,497.50

| Select User License | Single User License (one computer), Group User License (Up To Five Computers), Enterprise User License (Unlimited Computers Within Your Organization) |

|---|

Request Excerpt

Executive Summary

Chapter One: Introduction

1.1 Background to this report

1.2 Objective and scope of this report

1.3 Methodology of this report

1.4 Plan of this report

Chapter Two: Refractory Metals for Additive Manufacturing

2.1 Molybdenum

2.1.1 Cost advantages

2.1.2 Current status of additive manufacturing using molybdenum

2.2 Tungsten and tungsten alloys

2.2.1 Melting point advantages

2.2.2 Density advantages

2.2.3 Tungsten alloys for 3D printing

2.2.4 Current status of additive manufacturing using tungsten

2.3 Niobium

2.3.1 Strength and elasticity

2.3.2 Current status of additive manufacturing using niobium

2.4 Tantalum

2.4.1 Corrosion resistance

2.4.2 Current status of additive manufacturing using tantalum

2.5 Potential for 3D printing of Rhenium/rhenium alloys

2.6 Key points made in this chapter

Chapter Three: Supply Chain Analysis

3.1 Worldwide mining and extraction profile for refractory metals

3.2 Analysis of current and future refractory metal materials for 3D printing

3.2.1 Requirements for 3D-printed refractory metal materials

3.2.2 Specialized atomization and other powder manufacturing processes

3.2.3 Ten-year forecast of 3D printed refractory metals by type of metal

3.3 3D-printed refractory metals: Processes and machines

3.3.1 Metal binder jetting

3.3.2 Electron beam

3.3.3 Directed energy deposition

3.3.4 Powder bed fusion

3.4. Ten-year forecast of printers used for 3D-printed refractory metals

3.4.1 By type of AM process

3.4.2 By type of refractory metal

3.5 Key firms shaping the 3D-printed refractory metals market

3.6 Key points from this chapter

Chapter Four: Applications for Additive Manufacturing of Refractory Metals Products — Ten-Year Forecasts

3.1 Aerospace

3.1.1 Current applications for refractory metals

3.1.2 Ten-year forecasts of aerospace applications by type of metal

3.1.3 Ten-year forecasts by type of printing process

3.2 Medical and dental products

3.2.1 Current applications for refractory metals

3.2.2 Ten-year forecasts of medical and dental applications by type of metal

3.2.3 Ten-year forecasts by type of printing process

3.3 Nuclear power

3.3.1 Current applications for refractory metals

3.3.2 Ten-year forecasts of nuclear power applications by type of metal

3.3.3 Ten-year forecasts by type of printing process

3.4 Oil, gas and mining

3.4.1 Current applications for refractory metals

3.4.2 Ten-year forecasts of oil, gas and mining applications by type of metal

3.4.3 Ten-year forecasts by type of printing process

3.4 Other applications for 3D-printed refractory metals

3.5 Key points from this chapter

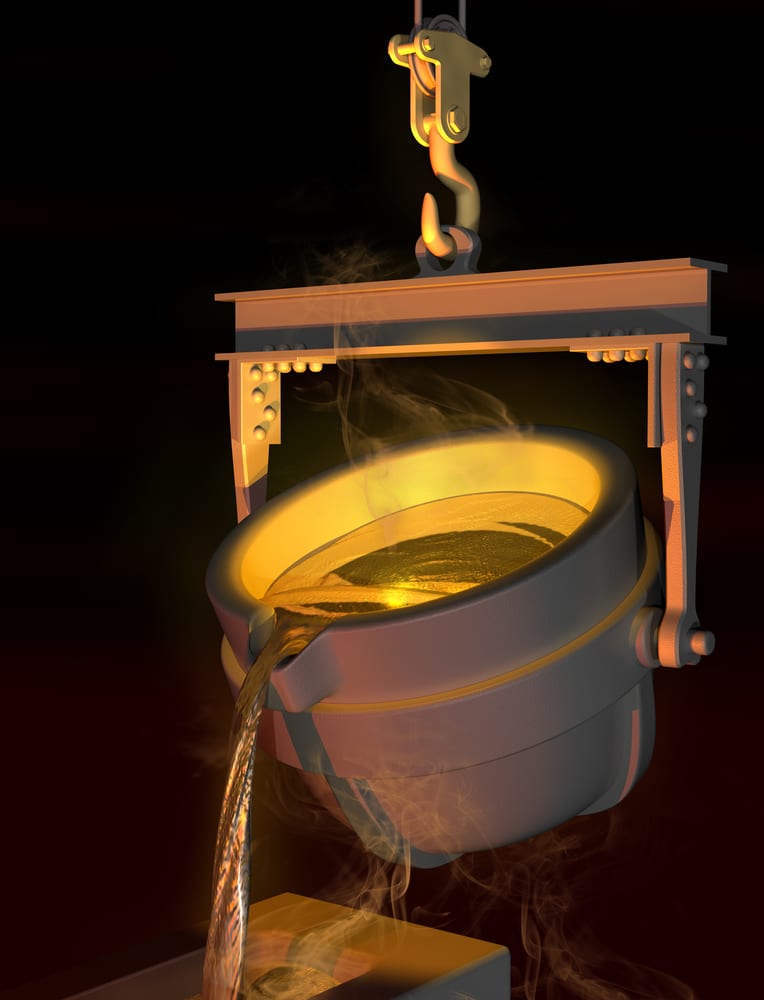

Refractory metals include niobium, molybdenum, tantalum, tungsten and rhenium. They are used in a broad range of applications where their exceptional heat and wear resistance are highly valued. Products built from these materials are produced using several manufacturing modalities. However, spurred on by the boom in additive metals manufacture, there has been a growing interest in 3D printing of refractory metals with applications in aerospace, medicine, dentistry, and the nuclear industry as well as in general industrial uses.

This report identifies the opportunities that 3D-printed refractory metals will create and quantifies these opportunities in the form of a detailed ten-year forecast. It also assesses the strategies of metals firms, printers firms and end users in the emerging 3D-printed refractory metal space.